Home

> Our Clients > Case

Studies > Columbia Aircraft Company

COLUMBIA AIRCRAFT COMPANY -

DEMAND PULL SYSTEM SOLUTIONS By Mark

Hoffman

I love spending time on the production floor. Although some say

I am the stereotypical engineer, I find one of my comfort zones

is being around people who get things done. When I have the opportunity

to visit production areas, I like to talk to these people and learn

what’s really going on; I have learned a lot through the years.

A question I ask frequently is, “What is preventing you

from doing your job?” The answer I hear second most is “Part

shortages.” The most common answer: “#&%* part shortages!”

Unplanned Part Shortages Limit Capacity

At

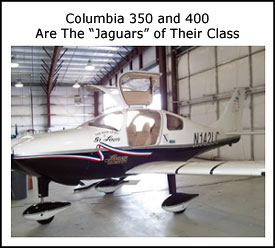

Columbia Aircraft Company in Bend, Oregon these words were spoken

often. Columbia Aircraft produces a beautiful 4-seat, single-engine

certified aircraft. (Their website, www.flycolumbia.com, has more

pictures of these gorgeous airplanes.) At

Columbia Aircraft Company in Bend, Oregon these words were spoken

often. Columbia Aircraft produces a beautiful 4-seat, single-engine

certified aircraft. (Their website, www.flycolumbia.com, has more

pictures of these gorgeous airplanes.)

When TCA first began working with Columbia,

customers had to sit on a waiting list for nearly 2 years before

they could take delivery of a new plane. Although the company sold

every plane it could make, management knew sales were well below

their full potential and felt Columbia Aircraft was losing customers

because of the long wait.

The Process

The plant in Bend fabricates and assembles body and structural

components and does final aircraft assembly. Additional components

and subassemblies are sourced from vendors and other Columbia Aircraft

facilities. Regulated by the FAA, these composite body aircraft

have a painstakingly defined production process; major steps in

include:

• Layup (fiberglass and resin worked into a full-scale

mold)

• Bonding

• Painting

• Sub-Assembly

• Upholstery

• Avionics

• Final Assembly

• Flight Test

Finding the Problem

Columbia Aircraft asked TCA to help increase production run rates

(output) by creating a Lean Manufacturing Facility Layout in the

Bend plant. In collaboration with Columbia Aircraft's own personnel,

we created a design and implementation team involving people from

Purchasing, Materials & Inventory Control, Production Control,

Fabrication, and Assembly. The team’s first step was to look

at production capacity at each stage of the process. We discovered

adequate machine capacity was available in each stage.

As you might suspect, one of the major issues was fabricated material

shortages. Fabrication just did not know when to make the needed

upstream part. To add to the problem, a newly implemented ERP system

was suspect – plant personnel did not trust it to build accurate

schedules for the entire plant.

Demand-Pull System Solution

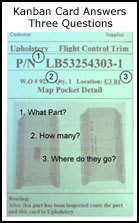

This situation was perfect for design and implementation of a

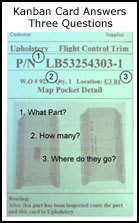

Demand-Pull System that could answer these questions:

• Which part to make?

• How many are needed?

• Where should they be delivered?

• When are the parts needed?

• What is my priority?

Kanban Approach

Early on, we decided to employ Kanban techniques to implement

the Demand-Pull System:

•

Kanban cards function as a replenishment trigger

that communicates consumption of parts to upstream operations.

While Kanban cards do have disadvantages (they can be lost), they’re

an easy way of knowing exactly what quantity of which part to

make when. •

Kanban cards function as a replenishment trigger

that communicates consumption of parts to upstream operations.

While Kanban cards do have disadvantages (they can be lost), they’re

an easy way of knowing exactly what quantity of which part to

make when.

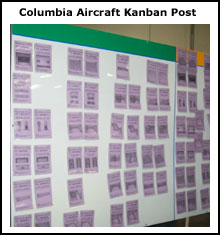

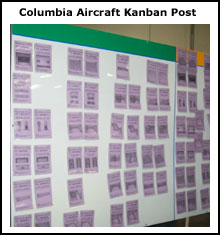

• Kanban posts are placed in each fabrication

cell and assembly area. Kanban cards are added to the post as

new requirements are received, then removed from the post as work

is completed. The Kanban post answers the 2 remaining questions

required for the Demand- Pull System: When are the parts needed?

What is my priority? Each Kanban post is a visual representation

of the current schedule for its production cell or area.

Kanban Post Scheduling Board

Each

Kanban post was divided into 3 zones – green, yellow, and

red; 2 rules govern how cards are placed on the board: Each

Kanban post was divided into 3 zones – green, yellow, and

red; 2 rules govern how cards are placed on the board:

- Depending on the urgency of the customer location’s need

for the part, the card is placed in any of the 3 zones; those

in the red or yellow zone take priority and are fabricated first.

- First-in first-out (FIFO) principles apply to cards in each

zone. Parts are fabricated in order, starting with the oldest

card on the board.

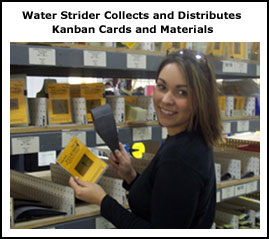

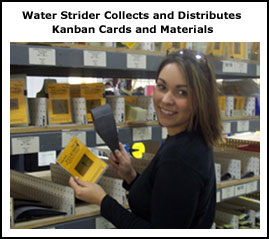

We used the “water strider” principle to deliver completed

parts (with a Kanban card) to the customer Kanban inventory location.

A water-strider is a material handler whose sole responsibility

is moving Kanban material and cards. The water strider also collects

Kanban cards from the customer Kanban inventory location and returns

them to the supplier cell’s Kanban post.

Kanban Cards

Just a few notes about the Kanban cards:

- • A magnetic strip on the cards and a steel Kanban post

board created an easy, clean method for placing the cards on the

post

- • The cards were about ¼ page size – not

too large, not too small

• Cards were laminated for durability

• All required information was placed on each card (part

number, supplier, customer, quantity/card, Kanban inventory location,

etc.) along with a picture of the part on the card – a very

useful addition

• Columbia Aircraft instituted a weekly Kanban card inventory

procedure to be sure cards weren’t lost.

The Kanban locations were sized correctly to allow comfortable

replenishment times and to accommodate any customer service

or rework demands. In our case, the run rate was 1 aircraft/day.

The team decided to use a min/max replenishment strategy –

with a min of 2 and a max of 5 for most production parts.

Results and Lessons

Before the Kanban Demand-Pull System was implemented, fabricated

part shortages were a daily occurrence. Now after several months

of operation, the system has made a fabricated part shortage rare.

And we learned it’s important to:

- • Keep up daily maintenance; the water strider was required

to maintain the system—making certain every part had a card

and cards were placed in the right Kanban post location with Kanban

inventory locations “perfect” in organization

• Move the cards and materials often; we found 4 times a

day worked well

• Develop a system to check on card loss (frequent inventory)

• Get the right information on the Kanban card

• Let the supplier cell/work station manage the Kanban post—and

do the red zone first

• Train, train, train frequently; once is not enough because

new people come on board, people change and people forget…train,

train, train.

Contact Us for a Free Assessment!

|

At

Columbia Aircraft Company in Bend, Oregon these words were spoken

often. Columbia Aircraft produces a beautiful 4-seat, single-engine

certified aircraft. (Their website, www.flycolumbia.com, has more

pictures of these gorgeous airplanes.)

At

Columbia Aircraft Company in Bend, Oregon these words were spoken

often. Columbia Aircraft produces a beautiful 4-seat, single-engine

certified aircraft. (Their website, www.flycolumbia.com, has more

pictures of these gorgeous airplanes.) •

Kanban cards function as a replenishment trigger

that communicates consumption of parts to upstream operations.

While Kanban cards do have disadvantages (they can be lost), they’re

an easy way of knowing exactly what quantity of which part to

make when.

•

Kanban cards function as a replenishment trigger

that communicates consumption of parts to upstream operations.

While Kanban cards do have disadvantages (they can be lost), they’re

an easy way of knowing exactly what quantity of which part to

make when. Each

Kanban post was divided into 3 zones – green, yellow, and

red; 2 rules govern how cards are placed on the board:

Each

Kanban post was divided into 3 zones – green, yellow, and

red; 2 rules govern how cards are placed on the board: