Home

> Practice Areas > Lean

Manufacturing Implementation / Coaching

LEAN MANUFACTURING IMPLEMENTATION

/ COACHING

Manufacturing

companies have a growing need to adopt World Class manufacturing

strategies, including Lean techniques. But these efforts are hindered by the absence of

technical understanding of Lean, and often there is little agreement on how to get started. Manufacturing

companies have a growing need to adopt World Class manufacturing

strategies, including Lean techniques. But these efforts are hindered by the absence of

technical understanding of Lean, and often there is little agreement on how to get started.

With TCA's capabilities

in operations consulting, and a deep expertise in Lean, we will

help you overcome the barriers and achieve the benefits of these powerful techniques in

a short time. We have the advantage of seeing lean manufacturing

implementation problems from a different perspective to introduce

creative and effective solutions.

Objectives

Successful implementation of Lean techniques begins with these objectives:

• Provide a course that results in

superior coaching to assist your Lean manufacturing implementation

• Educate the management team in Lean technologies and

other World Class philosophies

• Plan and carry out pilot applications

of Lean technologies

• Instruct an internal resource person in Lean education and World Class training and coordination

• Develop and document plans for expanding and implementing

Lean manufacturing systematically

Approach

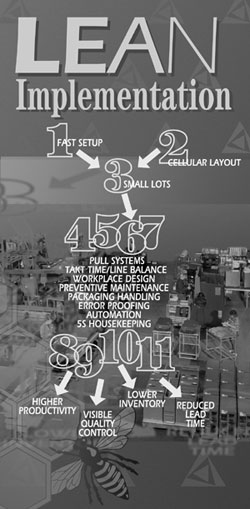

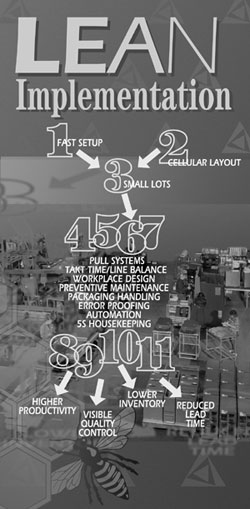

TCA has designed steps to achieve these objectives

with a minimum investment of time and effortt:

TCA Contributions

We support the execution of those steps by:

• Preparing and facilitating a management education and

planning workshop

• Helping you structure and document a long-term

vision and a pilot Lean manufacturing implementation project

• Preparing and delivering formal pilot team training

• Assisting in the development of secondary orientation

and education materials

• Supporting on-the-job training and pilot

teams

• Facilitating interim management project reviews

• Educatingan in-house resource person to carry out ongoing

Lean training and program management

• Delivering a presentation to summarize observations and

recommendations

• Participating in an expansion planning workshop

A critical dimension of TCA's support in implementing Lean manufacturing

is training. We believe the

key to technical improvement is rooted in understanding and acceptance

based on knowledge. Education is the vital element. We honor this

belief with carefully developed approaches

that reflect modern adult learning models. We enjoy training and

see it as our most important tool in assisting client companies

through difficult, but necessary changes.

Benefits

An investment in TCA's assistance with Lean manufacturing

will yield many benefits:

• You will overcome the inertia or "organizational

procrastination" that can delay the move to

Lean

• We will help you identify the best possible starting

point through carefully selected pilot projects

• Execution of the pilot projects will provide early economic

benefits—quality improvement, higher productivity improvement,

and waste reduction—which usually offset the entire cost of the pilot project

• Your management team will be knowledgeable in Lean concepts

and principles, having seen first-hand the effects of their application

• You will be spared the frustration and expense of false starts

• Expansion can be planned around a core group of grass

roots experts—those who planned and implemented the

pilot projects can now help other teams in the expansion phase

• Your in-house World Class program coordinator will be capable

of training and project management support in the expansion

phase

• Expansion will be based on a clear vision of

the role Lean can play in addressing vital business needs

and opportunities

Contact Us for a Free Assessment!

|

Manufacturing

companies have a growing need to adopt World Class manufacturing

strategies, including Lean techniques. But these efforts are hindered by the absence of

technical understanding of Lean, and often there is little agreement on how to get started.

Manufacturing

companies have a growing need to adopt World Class manufacturing

strategies, including Lean techniques. But these efforts are hindered by the absence of

technical understanding of Lean, and often there is little agreement on how to get started.